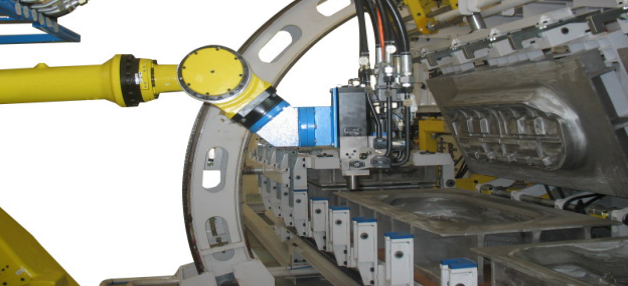

Automotive PU Seats & PU Parts Production line

Oval Conveyor Type

| THE CONSIST OF SEAT LINE | OVAL CONVEYOR LINE |

|---|---|

| High pressure PU foaming machine, 4 comp. & Mixing Head, MXL-4CD, MXL-4CS 3sets machine tanks, 250L ~ 500L Industrial robot Electric contro |

Mould carrier & Moulds Mould open & Close system Mould heating system Vacuum crus hing machine Safety system for working zone Gas exhaust and duct system |

| TECHNICAL DATA | |

|---|---|

| PU Machine | High pressure machine 4 comp. Mixin head system |

| Production method | Continuous type |

| PU injection | Automatic pouring into open mould |

| Mould carrier type | 1) Hydraulic open and close 2) Mechanial unit open and close 3) Steel guide bar open and close |

| Mould locking / Unlocking | Locking & Unlocking by air cylinder |

| Mould carrier | 20 ~ 30 Carriers |

| Speed | Approx. 100-200mm/sec, Changeable type |

| Cycle time | Approx. 10-15 sec |

| PU Curing time | Approx. 3.5-4min |

| Heating unit | 4 Kw/h (2carrier/one heating unit). Hot water by electric heating |

| Seat weight | Approx. Min 310g ~ Max 3,200g |

| Seat consists | Front cushion and back. rear cushion and back |

Turn Table Type

THE CONSIST OF HEADREST LINE

- High pressure PU foaming machine, 2comp. & Mixing head 0812 or1014-2C- Turn table and moulds

- Auto manipulator with mixing head cleaning unit

- Mould open & close by steel guide bar

- Electric cintrol

- Boiler

| TECHNICAL DATA | |

|---|---|

| PU Machine | High pressure machine 2 comp. Mixhead |

| Production method | stop & go moving type |

| Product | Foam in cover head rest or general head rest |

| PU injection | Automatic pouring into close mould by auto manipulator |

| Mould carrier type | Open and close by guide steel bar auto. Locking & unlocking by air unit |

| Mould carrier | 10 ~ 16 Carriers |

| Turn table size | Approx. 4m(D) x 1.6m(H) |

| Mdould carrier | Hot water or DOP cleaning by brush |

| Mixhead cleaning unit | Approx. 60 sec |

| The shot cycle time | By electric water boiler |

| Head rest weight | Approx. Min 150g ~ Max 350g |

| The required worker | 1 ~ 3 People |

| Yearly production capa | 1day - 8hr x 60min x 60sec ÷ 12sec = 2,400pcs 1month - 2,400 x 26days = 62,400pcs 1year - 624,000 x 12month = 748,800pcs |